Choosing the Right Sprayer: Compressor vs. Airless Paint Sprayer

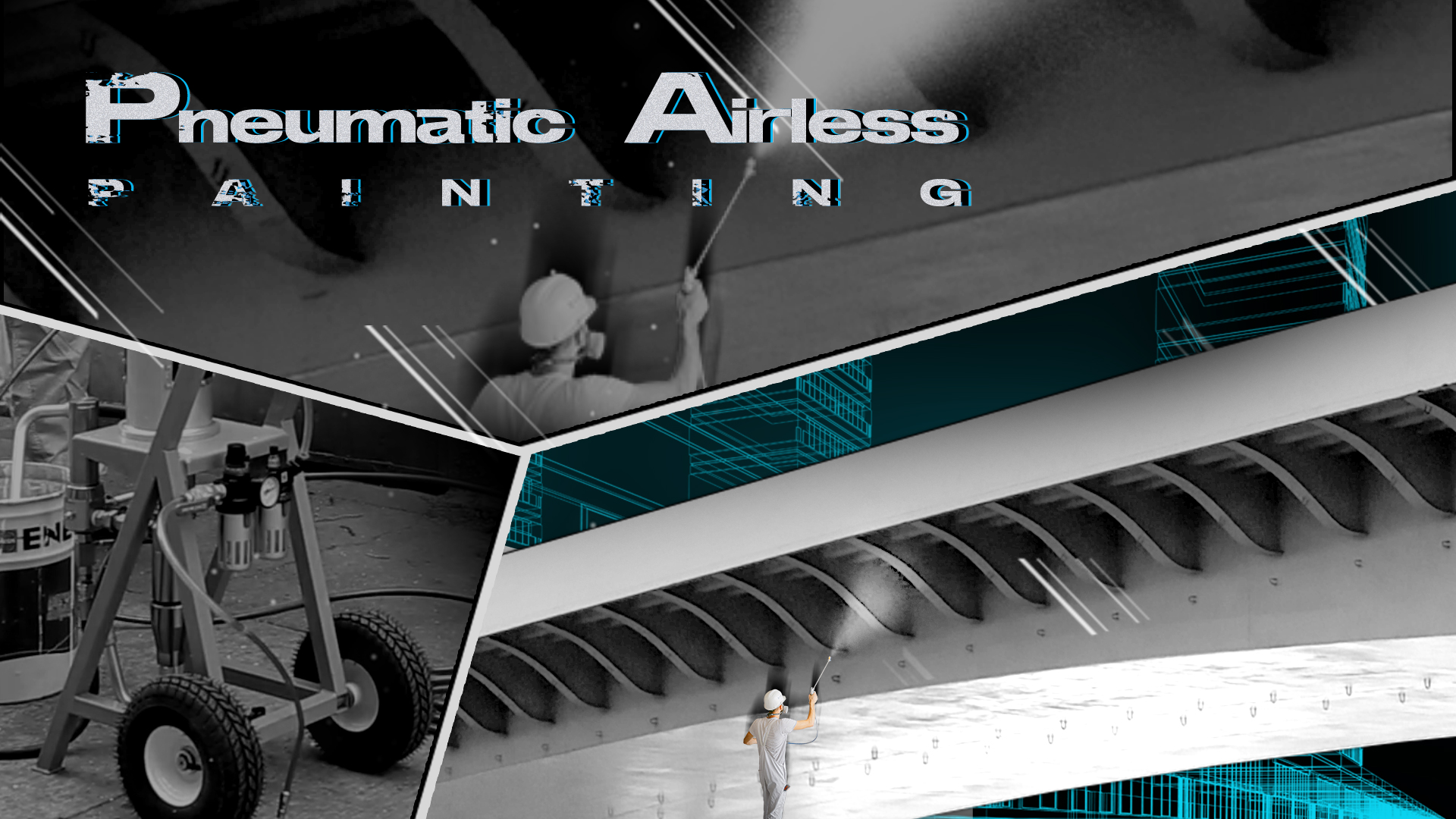

As you embark on a painting project—whether you’re refreshing a single room, sprucing up the exterior of a commercial building, or tackling a large industrial structure like a bridge—selecting the right spray method is essential.

You’ve already prepared the surfaces and chosen the colors, but one key decision still awaits: Should you go with an airless sprayer or a compressor paint sprayer?

This choice is a balance between the precision of traditional techniques and the efficiency of modern technology. Both options will get the job done, but they differ in their approach and the results they achieve.

Let’s take a closer look at each method to help you decide which is the best fit for your project, whether it’s a small room makeover or a large-scale industrial coating.

1. What is a Compressor Paint Sprayer?

A compressor sprayer, often referred to as a traditional air sprayer, uses compressed air to atomize the paint and apply it to surfaces.

(1)How It Works:

Compressed Air:

Paint is delivered from a pressurized tank to the spray gun through two hoses—one for atomizing air (50-75 psi) and the other for paint (25-30 psi).

Atomization Process:

Compressed air mixes with the paint at the nozzle, creating a fine mist that is applied to the surface. This method allows for precise control, making it ideal for detailed work on small parts or intricate structures.

Precision and Control:

Compressor sprayers are perfect for applications that require fine detail, such as automotive painting or furniture refinishing. They offer exceptional control over the spray pattern and paint flow with various nozzle and needle assemblies available.

Limitations:

While precise, compressor sprayers typically have lower transfer efficiency, meaning more paint is lost to overspray, leading to waste and additional cleanup. This method is also less efficient for larger projects due to its slower application speed.

2. What is an Airless Paint Sprayer?

Airless paint sprayers operate on a different principle than traditional sprayers. Instead of relying on compressed air to atomize the paint, they use high pressure (typically around 3000 psi) to compress the paint directly and push it through a high-pressure hose to a very small nozzle (called an orifice).

As the paint is ejected at this high pressure, it breaks into tiny droplets—a process known as atomization.

This method is popular in industrial applications because it’s effective for quickly and evenly covering large surfaces. Airless sprayers are used not only for homes and commercial buildings but also for coating larger structures like ships, bridges, and industrial projects.

Key Features:

High Pressure System:

In an airless sprayer, paint is pumped under high pressure through a specialized spray tip. The fluid emerges as a solid stream and atomizes into fine droplets upon contact with the air, creating a spray pattern.

Versatility:

Airless sprayers can handle a wide range of coatings, including high-viscosity materials like latex, elastomerics, and industrial primers, without needing dilution.

Advantages:

- Speed and Efficiency: Airless sprayers are much faster than traditional methods, making them ideal for covering large areas quickly—up to 10 times faster than brushing or rolling.

- Uniform Coverage: They provide a consistent, even coat of paint, which is especially important for achieving a professional finish on rough or textured surfaces.

- Industrial Applications: Airless sprayers are indispensable in industrial settings, used for painting ships, bridges, tanks, and other large structures where speed, efficiency, and durability are essential.

Limitations:

While efficient, airless sprayers offer less precision than compressor sprayers. High-pressure systems typically require careful handling and maintenance to ensure consistent performance. However, HiSprayer’s airless sprayers—with their optimized pump assembly, aviation aluminum filter, durable stainless steel frame, and smart control system—ensure stable performance and extended lifespan, even under high-intensity operations.

3. Key Differences Between Airless and Compressor Paint Sprayers

Transfer Efficiency:

Airless Sprayer: Higher transfer efficiency, with more paint reaching the surface and less lost to overspray.

Compressor Sprayer: Lower transfer efficiency, with more paint lost to overspray, resulting in increased waste and cleanup.

Performance:

Airless Sprayer: Excels in large-scale projects, delivering speed and uniform coverage on extensive surfaces like walls, fences, and industrial structures.

Compressor Sprayer: Best for small, detailed tasks that require precision and control, such as automotive painting or furniture refinishing.

Material Viscosity:

Airless Sprayer: Can handle a wide range of viscosities, making it suitable for thick coatings like latex and industrial primers.

Compressor Sprayer: Works best with thinner paints that can be easily atomized by compressed air.

Application:

Airless Sprayer: Ideal for big jobs, including residential, commercial, and industrial projects.

Compressor Sprayer: Suited for smaller, detail-oriented projects where control and a smooth finish are paramount.

Cost:

Airless Sprayer: Higher upfront cost but saves money over time due to reduced paint waste and faster application.

Compressor Sprayer: Generally less expensive initially but may incur higher costs due to increased paint usage and slower application speeds.

4. What’s the Best Choice for Your Project?

So, which spray method is right for you?

If your project requires speed, efficiency, and the ability to cover large areas quickly, an airless sprayer is your best bet. It’s particularly beneficial for industrial applications where time and uniform coverage are critical. However, if you’re focused on smaller projects that demand precision and a smooth finish, a compressor sprayer might be your preferred choice.

No matter what you choose, having the right equipment is essential—and that’s where HiSprayer comes in.

5. Why Choose HiSprayer ?

With over 20 years of expertise in the airless sprayer industry, HiSprayer is dedicated to developing and manufacturing high-quality airless paint sprayers. We blend innovation with durability, using only the finest materials—from Germany’s INA bearings and Japan’s IKO bearings to USA leather packings and robust stainless steel components. Every HiSprayer sprayer is built to last and perform at the highest level.

Our airless sprayers are designed to deliver professional-grade results, making your painting tasks faster, easier, and more efficient.

6. Ready to Elevate Your Painting Game?

Visit our website to explore our full range of airless sprayer products and accessories. With HiSprayer , your perfect paint finish is just a click away. Whether you’re painting a home or an industrial structure, HiSprayer has the expertise and equipment to get the job done right.

Post time: Aug-29-2024