What is a Pneumatic Paint Sprayer?

A pneumatic sprayer uses compressed air to power the spray pump, atomizing coatings (such as paint) at high pressure. This technology is widely used in industrial and construction applications due to its efficiency and precision.

Why Choose a Pneumatic Sprayer for Industrial Coating?

The pneumatic airless sprayer is an excellent choice for industrial coating projects, especially in hazardous environments like areas with explosive chemicals or flammable substances. Compared to other types of airless sprayers—such as electric or gas-powered sprayers—pneumatic models offer superior safety in these high-risk settings.

Innovative Design for Extreme Conditions

One drawback of traditional pneumatic sprayers is their vulnerability to cold environments, where the system can freeze due to icing. To address this issue, HiSprayer has introduced a redesigned mechanical reversing system in the HS370&HS370PRO series models. This upgrade enables the sprayers to perform reliably even in frigid conditions, preventing icing and ensuring consistent operation.

Models of HiSprayer Pneumatic Airless Sprayer

HiSprayer pneumatic airless sprayers are specifically designed to meet the needs of both small and large workshops where high volumes of paint products must be applied efficiently. With a high-quality piston pump, these sprayers deliver a superior finish while maintaining reliability. Additionally, the built-in large-capacity, high-pressure fluid filters help minimize debris, reducing tip blockages and wear during operation, ensuring consistent performance.

Model Overview

HiSprayer pneumatic airless sprayers are divided into two series and include a total of 9 models:

1. Series HS310 & HS330

Models:

· HS310-30

· HS330-45

· HS330-63

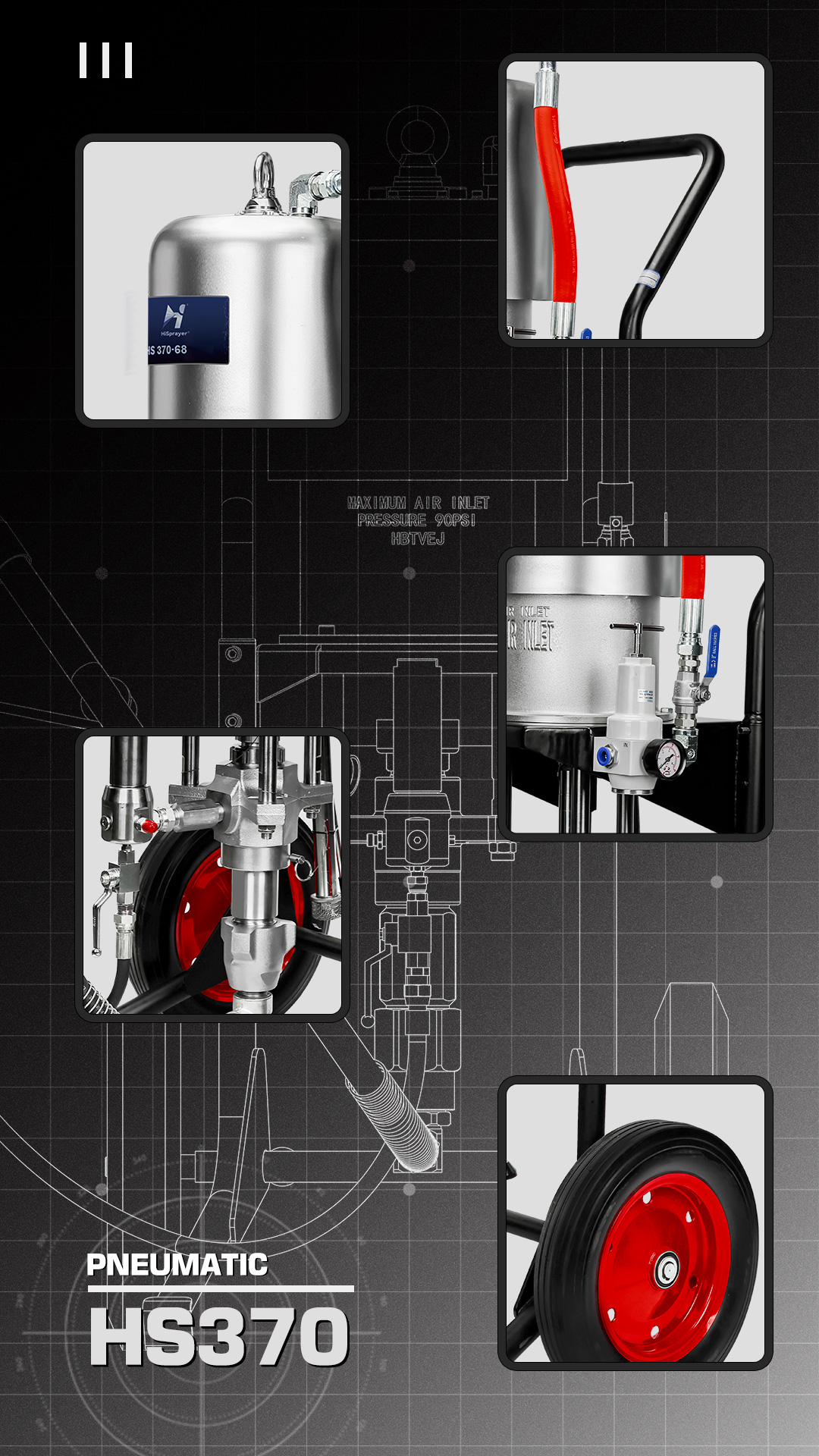

2. Series HS370 & HS370PRO

Models:

· HS370-45

· HS370-63

· HS370-68

· HS370PRO451

· HS370PRO631

· HS370PRO681

The “-XX” or “PROXX1” in each model represents the pressure ratio. For example, HS310-30 means that the fluid pressure ratio for this model is 30:1; HS370PRO451 means that the pressure ratio for this model is 45:1.

Since the different HiSprayer pneumatic airless sprayer series feature distinct structural designs, this article will focus on exploring the HS370 & HS370PRO series to highlight their unique characteristics and advantages.

The Difference between HS370 and HS370PRO

The key difference between the HS370 and HS370PRO lies in their pump assembly. While the HS370 features a standard pump assembly, the HS370PRO series is equipped with a pro-grade version. With upgraded manufacturing processes and a reinforced housing, the HS370PRO’s pump assembly offers enhanced durability and improved performance.

The advantages of HS370&HS370PRO

Advanced Anti-Freezing Mechanical Reversing System

The enhanced mechanical reversing system provides superior performance with a cutting-edge pneumatic motor that enables smooth, rapid direction changes for continuous operation. Its low air consumption boosts efficiency, and the anti-freezing design ensures reliable performance even in cold environments, preventing icing.

Additionally, the system offers easy maintenance and high reliability, ensuring consistent performance and reduced downtime for industrial painting applications.

Flexible Structural Design for Easy Transfer

Modular Design

The pneumatic motor and pump feature a split structure, making the equipment easier to clean, maintain, and repair. This design reduces downtime and simplifies component replacement. Additionally, the compact packaging enhances transportation efficiency.

Durable Cart Design

The durable cart design is detachable for easy maneuverability, making it ideal for long-distance and multi-site construction projects.

Durable Design for Long-Term Use

The durable pump assembly is built to withstand continuous high-intensity operation. Featuring carefully selected American packings and a chrome steel piston rod, it offers superior abrasion resistance, improved sealing, and strong pressure resistance for long-lasting performance.

All key pressure-bearing components are made from high-quality alloy steel, and the high-pressure valves are crafted from hard alloy, ensuring exceptional durability and reliable performance.

Enhanced Spraying Performance

More stable & reliable work performance

With the large flow rate and long stroke design, HS370 and HS370PRO pneumatic sprayer series provides more stable and reliable operation with a high-quality piston pump.

Dual Air Regulator Design

The dual air regulator design reduces component wear and preventing corrosion, ensuring greater durability and longevity of the machine.

User-Centered Design

Designed with the user in mind, the whole design delivers a better spray pattern. Small pressure fluctuations create uniform coating layers, resulting in improved paint quality.

Quick Specifications Comparison

| Model No. | HS370-45/HS370PRO45 | HS370-63/HS370PRO63 | HS370-68/HS370PRO68 |

| Max. Flow Rate | 24L/min | 18L/min | 12L/min |

| Fluid Pressure Ratio | 45:1 | 63:1 | 68:1 |

| Stroke Length | 120mm | 120mm | 120mm |

| Air Power Range | 3-7 Bar | 3-7 Bar | 3-7 Bar |

| Max. Discharge Pressure | 320 Bar | 440 Bar | 480 Bar |

| Max. Nozzle Size | 0.033” | 0.033” | 0.033” |

Conclusion

The HiSprayer HS370 & HS370PRO series pneumatic paint sprayers are designed to meet the demanding needs of industrial coating applications. With their advanced anti-freezing mechanical reversing system, modular structure for easy maintenance, and high-durability pump assembly, these sprayers provide reliable performance even in extreme conditions.

The HS370PRO series, featuring an upgraded pump assembly, further enhances durability and work performance, making it a superior choice for users requiring long-term, high-intensity operation. Additionally, the flexible and user-centered design ensures ease of use, efficient material application, and a consistently smooth finish.

Whether you are working in a hazardous environment, handling large-scale coating projects, or seeking a sprayer with superior durability and performance, the HiSprayer HS370 & HS370PRO series offer a robust and efficient solution tailored to painting needs.

Post time: Mar-14-2025