In various construction scenarios, the injection and mixing of two-component materials often face challenges such as insuffic

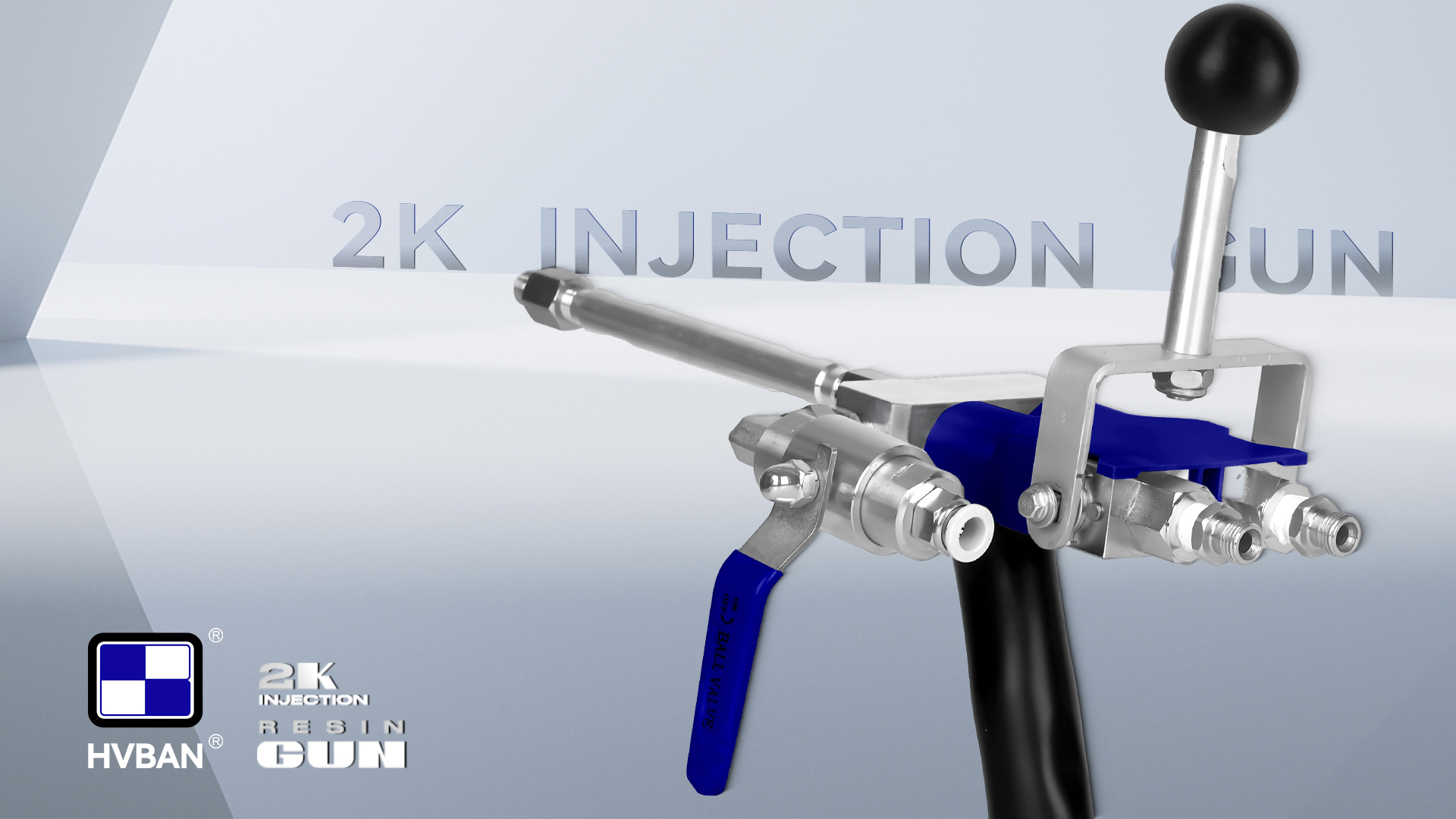

In many construction scenarios, injecting and mixing two-component materials often come with challenges like inadequate pressure, uneven material distribution, or complicated equipment maintenance. To help professionals overcome these obstacles, HVBAN has introduced the new 2K Injection Gun. Combining efficient injection, precision engineering, and adaptability for multiple environments, this tool is designed to handle complex applications in construction, underground engineering, and industrial projects effortlessly.

Have you encountered these common injection challenges on-site?

Many professional users have highlighted common injection-related issues that can directly affect project timelines and quality. Here are some frequent pain points:

- Insufficient Pressure, Incomplete Material Penetration

High-pressure demands often overwhelm many devices, resulting in insufficient output pressure that prevents materials from fully penetrating cracks, gaps, and other intricate structures. This leads to incomplete coverage and potential filling failures, particularly in structural repairs and crack injections, which can cause rework and project delays.

- Complex Maintenance, Impacting Efficiency

In high-intensity construction environments, frequent equipment cleaning and maintenance are unavoidable. However, traditional injection equipment is often time-consuming and complex to disassemble and clean, leading to extended downtime. Worse, improper maintenance can cause damage, increasing repair costs.

- Limited Functionality, Failing to Meet Diverse Material Needs

Different projects require different materials, but traditional injection equipment often handles only specific types. This forces users to have different tools for different tasks, increasing operational complexity and overall project costs.

The HVBAN 2K Injection Gun: A Tailored Solution for Multi-Scene Applications

The HVBAN 2K Injection Gun is designed specifically to solve the challenges encountered in injection tasks. Whether it’s handling high-pressure injections, simplifying equipment maintenance, or adapting to complex application scenarios, this tool is your go-to solution for completing a wide range of tasks efficiently.

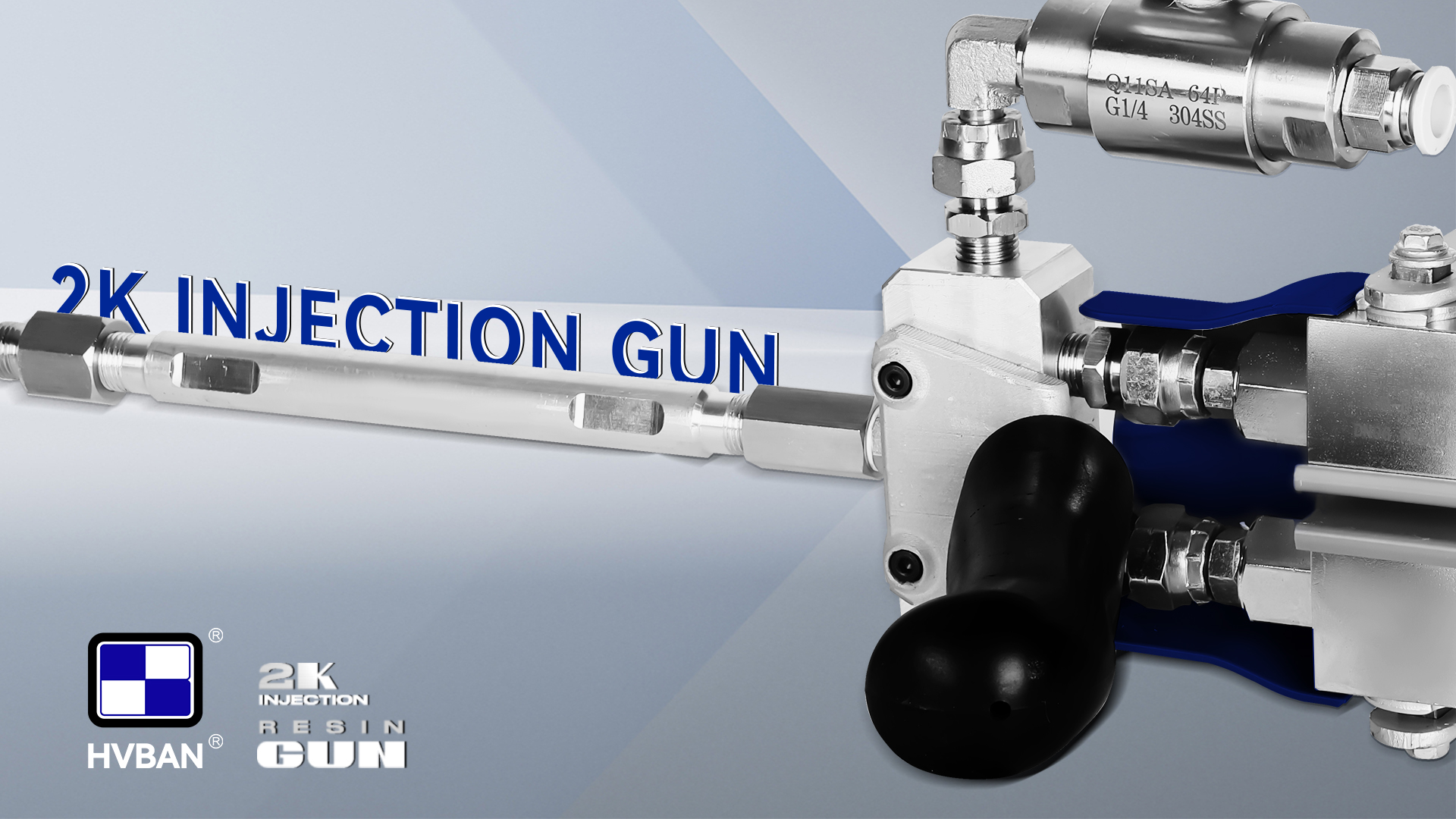

High-Pressure Injection Technology for Precise Material Penetration

Delivering a high output pressure of 23 MPa, the HVBAN 2K Injection Gun ensures that adhesives penetrate evenly into complex structures, especially when working with two-component resins (such as 1:1 ratio mixtures). This tool provides stable pressure during gap filling, crack repair, and underground material injections, ensuring full coverage and preventing incomplete filling due to low pressure.

Tool-Free Disassembly for Simplified Maintenance

Maintenance is a challenge every construction worker faces. With the HVBAN 2K Injection Gun’s tool-free disassembly design, cleaning and maintaining the equipment is fast and easy, minimizing downtime. You no longer need to worry about complex maintenance procedures holding up your project, and the simplified maintenance design reduces the risk of equipment failure over prolonged use.

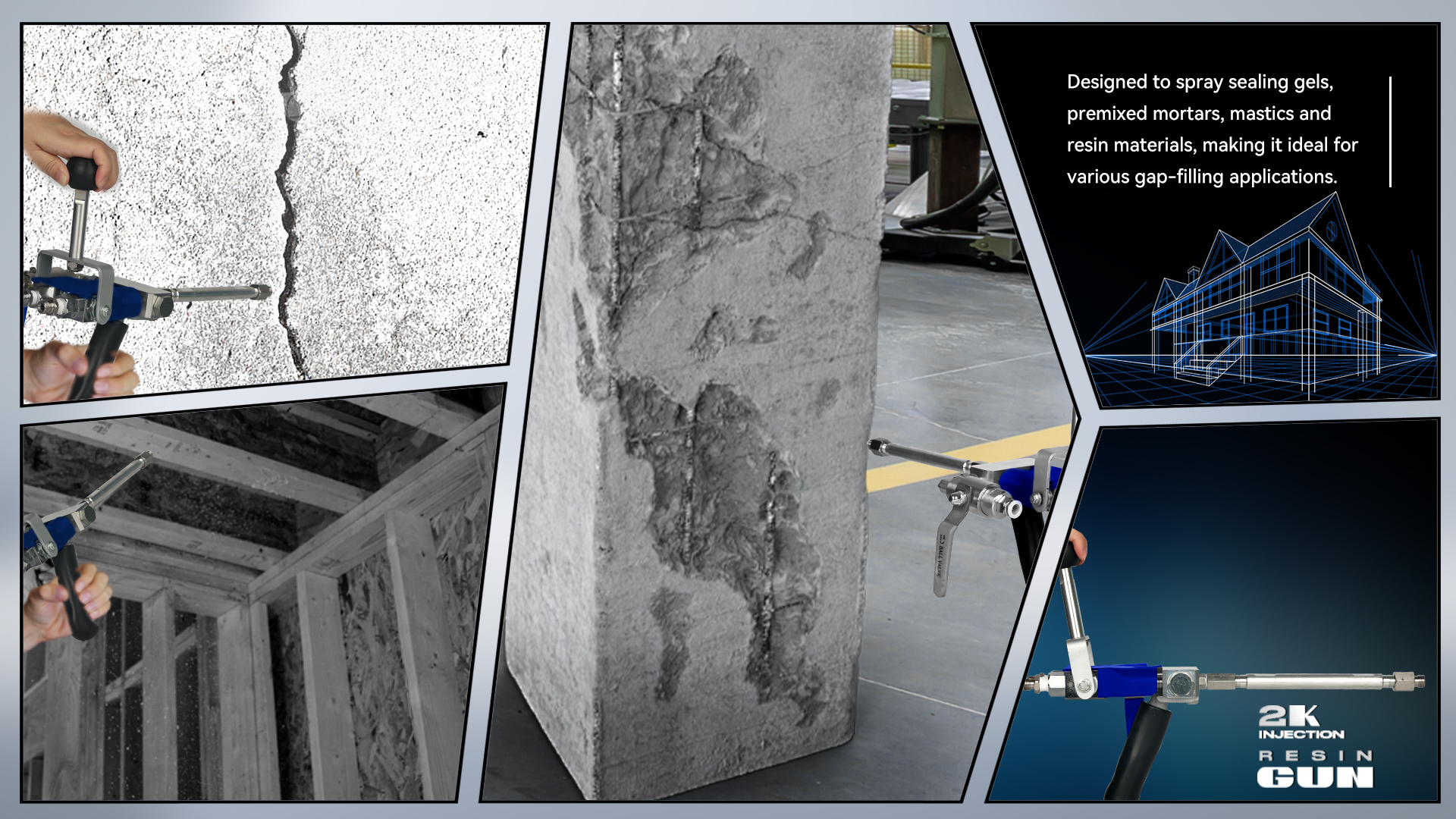

Supports a Wide Range of Materials, Adaptable to Various Scenarios

This injection gun isn’t just suited for injecting two-component materials like 1:1 resins; it’s also capable of performing precise injections in challenging settings, such as underground vaults, tunnels, crack repairs, basements, and elevator pits. Whatever your material needs, the HVBAN 2K Injection Gun offers a versatile and user-friendly injection solution.

Compatibility with Multiple Standard Interfaces for Flexible Adaptation

Designed with BSPT threading, the HVBAN 2K Injection Gun supports 1/4 NPSM and G1/4 standard interfaces, ensuring compatibility with various hoses and nozzles to meet diverse injection requirements. This high compatibility allows you to switch accessories seamlessly and adapt to different working conditions with ease.

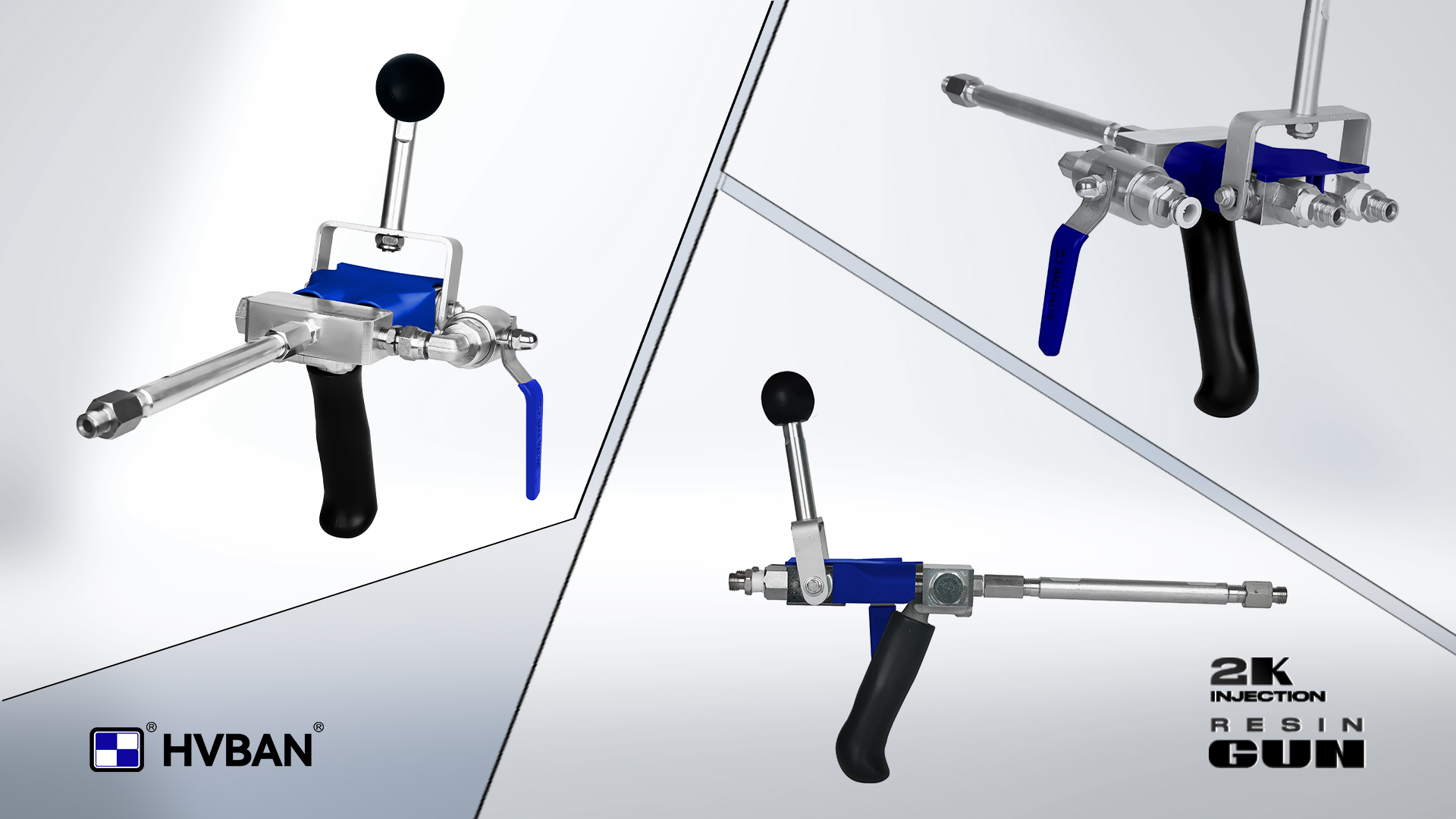

Built with High-Strength Materials for Long-Lasting Durability

Constructed from 6061 aluminum alloy and 304 stainless steel, the HVBAN 2K Injection Gun boasts excellent corrosion resistance and durability. Even under harsh construction conditions, this tool maintains stable performance, ensuring reliable operation in high-pressure environments and reducing equipment wear and failure rates.

Ergonomically Designed for Comfortable Operation

During long injection tasks, comfort is crucial. The HVBAN Injection Gun is ergonomically designed for extended use, providing a comfortable grip that reduces hand fatigue and allows users to work efficiently for longer periods without discomfort.

Why Choose the HVBAN 2K Injection Gun?

Professional construction workers understand that choosing the right tool can significantly enhance efficiency and project quality. The HVBAN 2K Injection Gun, with its powerful high-pressure injection technology, multifunctional adaptability, easy maintenance, and long-lasting durability, offers a superior construction experience. Whether you’re handling crack repairs, underground engineering, or complex structural filling, the HVBAN 2K Injection Gun is the trusted choice to help you succeed.

Choose the HVBAN 2K Injection Gun today and experience precision injection technology that ensures the smooth completion of every project.

Click here to learn more about the HVBAN 2K Injection Gun and embark on a new construction journey!

Post time: Sep-20-2024